Saliva is essential for oral health and homeostasis. A decrease in saliva production can cause damage to the oral mucosa, dentition, and basic activities such as eating and speaking, known as xerostomia. Reduced salivation is usually caused by medications, including various antihypertensives, diuretics, and antihistamines. Drug-induced xerostomia is reversible, but radiation therapy can cause permanent loss of saliva.

Microfluidic technology appeared in the early 1990s and has been gradually used in biomedical research due to its advantages of relatively low cost, fast and accurate processing, and supporting highly automated analysis. Polymeric materials have been widely used in the field of microfluidics due to their advantages of easy fabrication and low cost. Two of the most widely used polymers are polydimethylsiloxane (PDMS) and polymethylmethacrylate (PMMA), both of which are biocompatible and have their own properties. Combining PDMS and PMMA into a single microfluidic device can complement each other, reaping the advantages of each material while minimizing their limitations, leading to the development of new applications such as improved organ-on-a-chip.

PDMS

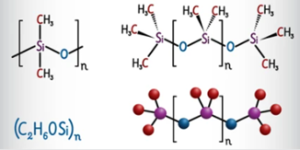

PDMS is a silicon-based elastomer with high gas permeability, flexibility, and light transmittance, suitable for bio-based microfluidic applications. But with the tendency of non-specific molecular adsorption and release of small non-cross-linked PDMS molecules, microchannels made of PDMS may absorb organic solvents and proteins, leading to clogging or even cell adhesion problems.

Polydimethylsiloxane (PDMS)

Polydimethylsiloxane (PDMS)

PMMA

PMMA is an acrylic-based thermoplastic with good mechanical stability, chemical resistivity, and high transparency. The refractive index (1.49) of PMMA exhibits glass-like optical clarity and transparency. Its advantages include inexpensiveness, lightweight, and good toughness, meanwhile, it offers easier and more cost-effective fabrication. The disadvantage is the unsuitability for the fabrication of integrated flexible elements, such as porous for cell culture, and conductive and stretchable microfluidic sensors.

Polymethylmethacrylate (PMMA)

Polymethylmethacrylate (PMMA)

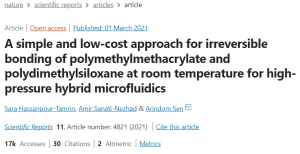

On March 1, 2021, a joint research team at the University of Calgary published an article titled “A simple and low-cost approach for irreversible bonding of polymethylmethacrylate and polydimethylsiloxane at room temperature for high-pressure hybrid microfluidics” in the journal Scientific Reports. This study developed a new method to mediate a strong bond between PMMA and PDMS layers at room temperature in less than 5 min using biocompatible adhesive tape and oxygen plasma treatment. The bonded microfluidic devices are hydrolytically stable and can withstand large fluid influxes without leaking.

Overview of PMMA and PDMS Bonding Methods

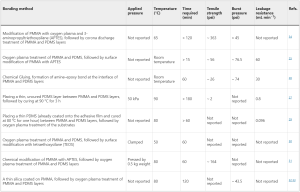

Microfluidic devices combining elastomers and thermoplastics have been widely reported for medical and industrial applications. However, the combination of such materials is challenging due to their different physicochemical properties. Table 1 summarizes various techniques previously reported for bonding PDMS to PMMA. There are two types of bonding methods: direct bonding (no additional material at the bonding interface) and indirect bonding (adhesive is added at the interface). Surface modification using oxygen plasma treatment increases the surface energy and facilitates the irreversible bonding of PDMS to PDMS or glass substrates through the interaction of functionalized silanol groups (SiOH), leading to the formation of strong Si–O–Si key. However, PDMS and PMMA cannot be directly bonded in this way because PDMS and PMMA exhibit only weak van der Waals interactions after oxygen plasma treatment unless chemically modified. However, the direct bonding technology based on chemical modification not only needs to be optimized according to the surface treatment conditions, but also requires high temperature and pressure to achieve bonding, which may lead to clogging and deformation of microchannels.

Various methods of bonding PMMA and PDMS layers

Various methods of bonding PMMA and PDMS layers

Indirect bonding is a method that uses a liquid or solid adhesive as an intermediate layer at the interface of two dissimilar materials. Using liquid adhesives to create a permanent bond between PMMA and PDMS requires applying the adhesive between these surfaces and then hardening it through processes such as chemical reaction, UV radiation, solvent evaporation, heating, or cooling. But the low tensile strength and leakage reported by the study suggested that the bonds produced were not strong. Additionally, liquid adhesives tend to flow into and clog microchannels, thus using them in microfluidic devices is limited.

Solid binders significantly reduced microchannel clogging compared with liquid binders. Pressure-sensitive adhesive (PSA) is a solid adhesive film mainly composed of elastomers (rubber, acrylate, and silicone). Commercial PSA tape is inexpensive, easy to use, and can reduce the time required to assemble microfluidic devices. A layer of adhesive of uniform thickness is used on the interface between the two substrates, which will not deform and enter the microchannels under high pressure or high temperature. Furthermore, their use is easily scalable, thereby supporting large-scale production of microfluidic devices. Importantly, they exhibit good biocompatibility, making them good candidates for fabricating microfluidic channels in biomedical analytical devices. However, reports describing the use of PSA to produce PDMS-PMMA hybrid microfluidic devices are very limited. The main reason is that the adhesion between PSA tape and PDMS is not strong.

New bonding strategy

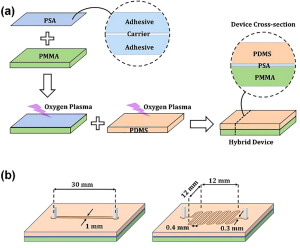

With a double-sided PSA, the adhesive is applied to both sides of a flexible plastic film (carrier) to facilitate the adhesion of two different materials. A schematic diagram of the binding process is shown. First, the PMMA substrate was gently cleaned using isopropanol solvent and a wet wipe, and then the PSA was laminated onto the PMMA substrate. Squeeze the PMMA-PSA structure with clamps for 2 min to facilitate bonding. Then, the PSA and PDMS surfaces that have been laminated on PMMA were exposed to oxygen plasma treatment for 1 min under the working conditions of 15 W, 25 mL min-1 oxygen flow, and a chamber pressure of 700 mTorr to increase their surface energy and promote the combination of two materials. Finally, place the treated PDMS layer on top of the PSA and keep the whole structure in conformal contact (slight squeeze between thumb and index finger) for 10–15 s at room temperature (23 °C).

Bonding strategy and design of microchannels

Bonding strategy and design of microchannels

Conclusion and Outlook

This study describes a simple, fast, efficient, and low-cost method for bonding hybrid materials in microfluidic devices. PMMA and PDMS were bonded together using a double-sided PSA adhesive at room temperature in less than 5 minutes. A key step in the process is oxygen plasma treatment, which causes the PSA and PDMS layers to form irreversible bonds without causing microchannel clogging or deformation. The bond is hydrolytically stable and can withstand high fluid flow rates and pressures. Tensile and burst pressure tests show high bond strength. The simplicity of this new bonding method will facilitate the innovation of PDMS-based microfluidic devices and support rapid production for a variety of biomedical applications, such as centrifugal microfluidic assays, liquid chromatography separations, microvalve/micropump fabrication, and gas-controlled cytochemical thermostats.

Reference:

Hassanpour-Tamrin, et al. A simple and low-cost approach for irreversible bonding of polymethylmethacrylate and polydimethylsiloxane at room temperature for high-pressure hybrid microfluidics. Sci Rep 11, 4821 (2021).

Related Services: