Organ on a chip

The organ chip is a chip system developed based on microfluidic technology, which can simulate different organs of the human body. This technology implants human cells into the chip, and the chip simulates the human body environment (such as pressure, shear stress, and concentration gradient) to form an in vitro model, and realizes tests that are closest to the real internal environment, such as drug screening, drug safety testing, and food safety testing. It is a powerful tool for constructing complex disease models and conducting preclinical new drug development.

3D bioprinting

3D bioprinting mainly uses cells, biological hormones, growth factors, intercellular substances, and other substances to print out human living tissues with biological functions. The emergence of this technology can help scientists build high-bionic chip models that simulate the microstructure and function of the heart, lungs, kidneys, muscles, tongue, bone marrow, and intestines in batches. It is widely used in many fields such as cell development mechanism research, pathogenic mechanism research, and drug development.

Figure 1. Fabrication of complex biological structures using 3D printing technology [1]

Figure 1. Fabrication of complex biological structures using 3D printing technology [1]

Organ chip engineering simulates the real tissue or organ environment by controlling cells, extracellular matrix (ECM), and other microenvironmental factors to elucidate the physiological or pathological mechanisms of cellular essence. Existing chip models are mainly based on polydimethylsiloxane (PDMS) microfluidic devices, while traditional soft lithography requires cumbersome production procedures with long cycle times and high costs. 3D printing technology can effectively design and automatically print micron-scale devices, and construct complex organs or tissues by precisely manipulating cells and biological materials. The popularity of 3D printing provides more options for the application of organ chips. The combination of 3D printing and microfluidic technology in the construction of organ chips can provide more complex flow channels or chambers, presenting in vivo structures with 3D cell distribution, heterogeneity, and organization-specific functions.

Figure 2. Interpenetration of 3D printing and microfluidics in organ-on-a-chip fabrication [2]

Figure 2. Interpenetration of 3D printing and microfluidics in organ-on-a-chip fabrication [2]

Printing material

- Natural materials: derived from various organisms and highly biocompatible, including alginate, gellan gum, collagen, fibrin, and gelatin. These materials often form hydrogels called bioinks, which are used to encapsulate cells in 3D cell printing. The bioink is viscoelastic and has a high water content, which protects the cells during the printing process.

- Synthetic materials: such as Polycaprolactone (PCL), silicone, and Pluronic F127. These biocompatible synthetic polymers often exhibit low cytotoxicity and biological inertness, and can be used to construct the shell portion of a whole organ on a chip.

3D printing technology

With the continuous development of precise cell/ECM localization research, 3D printing has become an effective technology for fabricating complex biological structures. Creative Biolabs offers a variety of different 3D printing strategies used to realize the construction of organ-on-a-chip, including micro-extrusion method, inkjet method, and laser-assisted printing method.

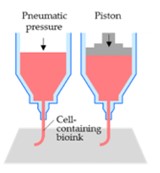

- Micro extrusion printing method

Microextrusion-based systems are equipped with multiple print heads containing different types of cells or bioink materials for the fabrication of complex heterogeneous structures. When using multiple print heads, we consider nozzle position, spacing, print speed, distribution force, and nozzle diameter. The selected bioink must be sufficiently viscous to maintain the 3D shape of the developed organ.

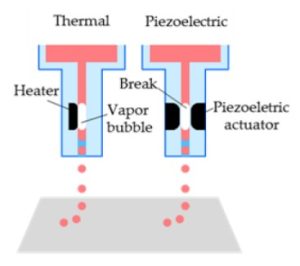

- Inkjet printing method

Inkjet printing is the delivery of a controlled volume (droplet) of a cell suspension at a predetermined location, where the liquid is vaporized into microbubbles through an electrically heated nozzle or piezoelectric actuator, and finally emitted from the nozzle in the form of droplets.

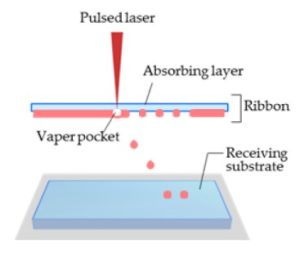

- Laser Assisted Printing

In laser-assisted printing systems, biological structures can be patterned or directly fabricated by laser-induced forward transfer. Laser-assisted printing overcomes some of the limitations of micro-extrusion and inkjet printing methods, for example, the accuracy of laser aiming itself and the highest resolution of jetted droplets.

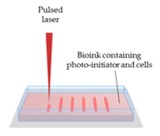

- Stereolithography (SLA) printing method

Stereolithography, another form of laser-assisted printing, is capable of producing complex 3D structures and is one of the most powerful 3D printing techniques. The basic mechanism of stereolithography is the curing of liquid photopolymers by laser-induced photopolymerization at ultraviolet, infrared, or visible wavelengths. After photopolymerization of the 3D pattern of the 3D model, the 3D structure is obtained by layer-by-layer accumulation.

Reference:

[1] Yi H G, et al. 3D printing of organs-on-chips. Bioengineering. 2017, 4(1): 10.

[2] Mi S L, et al. The crossing and integration between microfluidic technology and 3D printing for organ-on-chips. J. Mater. Chem. B. 2018,6: 6191-6206.

Related Services: