In recent decades, the integration of microfluidic devices and micro-scale multi-drive technology has greatly promoted progress in related fields. In particular, microbubbles play an increasingly important role in microfluidics because they have unique characteristics and can produce specific responses to different energy sources and gas-liquid interactions. Many effective and powerful bubble-based micromanipulation strategies have been developed and improved to achieve various non-invasive, selective, and precise manipulations on a microscale. This article mainly introduces the morphological characteristics and formation of microbubbles.

1 Introduction

Microfluidics is the science of microscale fluid mechanics that guides the design of microfluidic devices and their applications in biology, chemistry, medicine, and physics. The geometric design of channels in custom microfluidic devices has proven to be a powerful tool for high-throughput and non-invasive operations involving biological targets. However, the pre-designed fixed internal geometry and streamlined operation of the microfluidic device make it difficult to perform multiple complicated micromanipulations. In the past few decades, with optical, acoustic, electrical, and magnetic field forces, microfluidic devices have been given more functions. However, these external field forces may directly or indirectly destroy biological targets and cannot perform accurate and selective operations. As the most common gas phase in micro-scale fluids, microbubbles have been combined with microfluidics to achieve micromanipulations, especially for the treatment of biological targets. Although microbubbles formed through spontaneous nucleation under certain conditions in the microfluidic environment have potential “destructive” properties, they have proven to be effective methods in solving the challenges of achieving a variety of complex biocompatible micromanipulation goals.

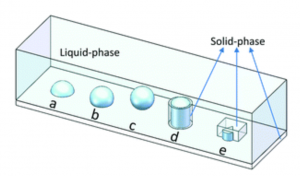

The main types of bubbles and their applications in microfluidic operations are shown in Fig. 1.

Fig. 1 Application of microbubbles in microfluidic operations

2 The generation of bubbles in microfluidics

Generating microbubbles with controllable morphological characteristics (such as size, shape, and location) is the first step before applying them to a variety of micromanipulations. Generally, the morphological characteristics of microbubbles also determine the control of their behaviors and how to manipulate the target.

Although bubbles can form many irregular structures and undergo intricate changes over time, regular and unchanging shapes are necessary for stable operation in a fluid environment. According to the principle of energy minimization, the surface tension of the bubble will make its gas-liquid interface area as small as possible. In the initial condition of a relatively static flow field, the free surface of the bubble is infinitely close to a spherical shape. Considering the influence of the solid boundary, the more common bubble shapes in microfluidics are spherical, truncated spherical, cylindrical, and restricted spherical (Fig. 2). In most cases, the shape of the bubble depends on the configuration and expected functions of the microfluidic device. However, this does not mean that a bubble with a specific shape has a unique application range. In fact, due to multiple influencing factors, there is no obvious causal relationship between the bubble shape and its application.

Fig. 2 Bubbles of different shapes in microfluidics

Bubbles are gases encapsulated in liquids (and solids), so the most important aspect of bubble generation in fluids is the source of the gas. Therefore, bubble generation can be divided into two categories: gas transfer and gas generation. Table 1 summarizes common effective bubble generation methods based on applications and structural characteristics of microfluidic devices, including gas delivery methods of injection, capture, and extrusion, and gas generation methods of electrolysis, heating, and chemical reactions. In addition, we list the appropriate bubble shape and size obtained from each method for micromanipulation, as well as the main advantages and disadvantages of each method.

Table 1 Bubble generation methods and their respective characteristics

3 Theoretical background

There are various working mechanisms of bubbles in microfluidics. Here, we classify them according to their formation methods to explain the theoretical background concisely.

3.1 Acoustic microbubbles

In nature, the resonance phenomenon helps to produce syllables from our throat and prevents ultraviolet rays from causing serious damage to biological functions. Similarly, resonance phenomena also occur in microfluidic devices containing microbubbles.

Under the periodic drive of sound waves, the microbubbles react to pressure and exhibit their full potential energy, thus vibrating in the fluid. They are often referred to as acoustically oscillating bubbles because they usually exhibit volume oscillations or reciprocating vibrations along the axis.

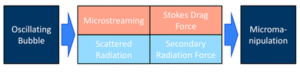

When bubbles oscillate under the excitation of a sound field, they can apply force to an object in two ways for micromanipulation. Fig. 3 briefly shows the mechanism of these two different forces: Stokes resistance and secondary radiation force. In addition to these two forces, the micromanipulation object in the microfluidic device is also affected by the main acoustic radiation force. However, when the size of the object is much smaller than the wavelength of the sound wave, the primary acoustic radiation force is so small that it can be ignored.

Fig. 3 Use of oscillating bubbles to perform micromanipulations in two ways

3.2 Thermodynamic microbubbles

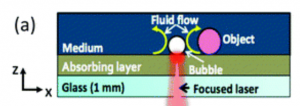

The thermodynamic bubbles we mentioned here are produced by the thermal effect generated by the laser. Like acoustic bubbles, thermodynamic bubbles can also act as a medium. Fig. 4 depicts the selective generation of laser-induced bubbles on a light-absorbing substrate that is heated by the laser to create a temperature gradient in the liquid surrounding the bubbles. The existence of the temperature gradient will generate hot capillary flow at the gas-liquid interface, thereby generating microcirculation.

Fig. 4 The theoretical streamline of a bubble that oscillates along an axis

3.3 Chemical microbubbles

Clever use of the chemical reaction in the gas generator can provide a certain amount and direction of momentum for the bubble when it is generated. This brings new possibilities for micromanipulation.

Among many types of chemical reactions that can generate gas, water electrolysis is a simple and effective method to generate microbubbles of a design size at a specific location in a microfluidic environment. The speed of bubble formation in the electrolysis reaction is directly related to the current intensity (for example, 2H + + 2e − → H 2(g) is used for the cathode reaction), so the initial parameters of the bubble, including its size and momentum, can be easily controlled. This provides a basis for manipulating target micro-objects by moving the gas-liquid interface. Due to the inherent low-momentum bubble generation and non-toxic reaction environment of water electrolysis, it is mainly used in relatively accurate biological target operations.

As mentioned above, the bubble acts as an intermediate medium to convert other forms of energy such as sound energy, thermal energy, and chemical energy into various forces that act on the target object to achieve micromanipulation. Each of the three types of bubbles introduced here has unique characteristics. Namely, sound bubbles can be excited at specific frequencies with little requirement on the propagation medium, and the sound intensity used is generally far below the threshold that causes damage to the human body. And laser induced thermal bubbles, by adding a feedback device, can easily realize bubble synergy and closed-loop control with high operating efficiency and high precision. And chemical bubbles have high kinetic energy and do not require a long bubble lifetime. The characteristics of bubbles determine their applicable fields.