3D printing technology, a kind of rapid prototyping technology, is a method based on digital model files to construct objects by stacking and accumulating layer by layer (also known as the “lamination method”), using adhesive materials such as powdered metal or plastic. In the past, 3D printing technology was usually used to realize model manufacturing. However, with the continuous development and progress of technology, this technology has been gradually used in the direct manufacturing and production of some commodities, especially some products with high-value applications.

Paper-based microfluidics, a subfield focused on the fabrication of field-useable devices using porous materials, is recognized as an excellent platform for time-critical health as well as environmental testing outside the laboratory setting. The porous nature of the material ensures its fluidity. Specifically, it enables the transport of liquid samples and internal reagents through capillary action, enabling automated testing without the need for external pumps to provide power. In addition, equipment based on this technology is very suitable for field applications because it does not require trained technicians or expensive pump equipment. However, a major challenge in developing effective use equipment for specific application scenarios is achieving the required device stability and analytical performance, meanwhile balancing the needs of other applications and considering the ease of use for operators, cost, manufacturability, etc.

3D printing technology has great potential to solve the above problems and challenges and promote the development of paper-based microfluidic devices. It can utilize several tools and methods to achieve the definition of multilayer microfluidic channels, the preparation of new porous materials and the construction of non-porous support components, and the seamlessly integrated assembly of multiple device components, thereby expanding the device capabilities and manufacturability.

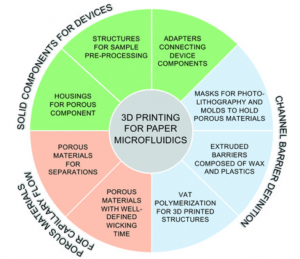

Recently, the team led by Professor Elain Fu from Oregon State University in the United States reviewed the research progress of the application of 3D printing technology in paper-based microfluidic devices in recent years. Three categories of research work are systematically concluded in this review: 1) Paper-based microfluidic elements with solid-state support structures; 2) Definition of channel barriers in existing porous materials; 3) The value of porous channels in advancing the development of paper-based microfluidic devices. The review has been successfully published online in Lab on a Chip.

At the end of the review, the author also expounded on the research focus and prospects of 3D printing technology in the application of paper-based microfluidics: 1) Direct 3D printing of porous materials has the characteristics suitable for the application of paper-based microfluidic devices, which has a high value for analytical development of next-generation paper-based microfluidic devices; 2) The use of 3D printing technology to integrate multiple materials into additive manufacturing processes will greatly advance the development of next-generation paper-based microfluidic analysis; 3) Although current 3D printing technologies are not comparable to some existing paper microfluidic manufacturing methods (e.g., the lateral flow analysis) in terms of scale, material cost and manufacturing time, in the near future, 3D printing manufacturing practice may be able to provide some level of scale production, as there is already work to build 3D printing farms. In addition, 3D printing could enable decentralized manufacturing of diagnostic technologies even if it is not comparable to some manufacturing technologies on a larger scale.