Microfluidics refers to the science and technology involved in systems that use micropipes (tens to hundreds of microns in size) to process or manipulate tiny fluids. It is an emerging interdisciplinary involving chemistry, fluid physics, microelectronics, new materials, biology, and biomedical engineering. It can integrate the process of analyzing samples in the fields of biology, chemistry, and medicine, including preparation, reaction, separation, detection, and other basic units into a micron-scale chip, and automatically complete the entire analysis process. Because of its features such as miniaturization and integration, microfluidic devices are usually called microfluidic chips, and also known as Lab on a Chip and micro-Total Analytical System.

1. The history of microfluidics development

Microfluidics is accompanied by the development of micro-electromechanical processing system (MEMS) technology. MEMS technology refers to the use of semiconductor technology to miniaturize real-life mechanical systems to form micro-electromechanical systems. Microfluidics is based on the characteristics of MEMS technology, microfilming a large laboratory system on a glass or plastic substrate, thereby replicating the entire process of complex biological and chemical reactions, and completing experiments quickly and automatically. It is characterized by constructing fluid-containing channels, reaction chambers, and other functional components on a micrometer scale, and manipulating the movement of micrometer-sized fluids in tiny spaces, thereby constructing a complete chemical or biological laboratory.

In the 1990s, Manz and Widmer et al. used chips to achieve electrophoretic separation previously completed in capillary tubes, and first proposed the concept of Miniaturized Total Analysis System (μTAS) in 1990. After that, micropumps and flow sensors were gradually developed. The emergence of the fluid processing concept based on the integration of a complete laboratory analysis system into a chip has spawned the research of microfluidic chips worldwide.

2. Advantages and application scenarios of microfluidic chips

(1) Technical advantages

Microfluidic chip technology developed based on MEMS is known as one of the seven technologies that will change the future. Compared with traditional methods, it has the following advantages:

1.1 Miniaturization

Microfluidic technology can concentrate the entire process of sample detection on a chip of a few square centimeters. Through the integration of different modules such as the design of the liquid flow channel, the placement of the microvalve, and the design of the liquid cavity, the detection operation process is comprehensively completed, finally making the whole process of detection miniaturized.

1.2 High throughput

The microfluidic chip can be designed in the form of multi-channels. The sample to be tested can be divided into multiple reaction units through the micro-channel network. Since the reaction units are isolated from each other and do not interfere with each other, multiple tests can be performed on a single sample at the same time as needed. Compared with conventional detection, the detection time is significantly shortened, the detection efficiency is improved, and the detection is high-throughput.

1.3 Small sample demand

The sample volume required for detection on a microfluidic chip often only needs to be microliters or even nanoscale. At the same time, due to its high-throughput characteristics, multiple tests can be performed on samples collected at one time, so it is more advantageous for the detection of samples that are not easy to obtain.

1.4 Low reagent consumption

Due to the miniaturization characteristics of the microfluidic chip, the internal reaction unit cavity is also very small, making the total volume of the entire reaction system very small, and greatly reducing the consumption of reagents compared with the traditional detection system.

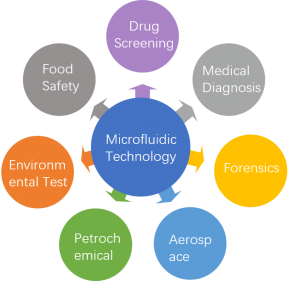

(2) Application scenarios

The above-mentioned obvious advantages of microfluidic chips bring them very broad application prospects in different fields. For example, the field of in vitro diagnostics, which is most closely integrated with microfluidic chips, can display its own characteristics in IVD subdivisions such as biochemical analysis, immunodiagnosis, and molecular diagnosis, and has great potential to replace traditional IVD detection methods. In addition, the advantages in cell separation can greatly improve the detection rate and purity of circulating tumor cells, thereby providing key support for the treatment of related cancers. In the field of drug screening, such as stem cell chips, it can overcome the limitations of existing stem cells for in vitro research, by accurately controlling various factors in the stem cell microenvironment in real time, and simulating the complex environment of stem cell growth and differentiation as much as possible.

3. Introduction to Microfluidic Technology

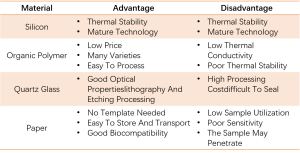

(1) Materials of microfluidic chip

The materials of microfluidic chips are mainly divided into silicon wafers, glass, PDMS, and paper. The specific advantages and disadvantages are shown in the table below.

(2) Microfluidic chip manufacturing technology

There are many manufacturing technologies for microfluidic chips, which can be roughly divided into the following categories: photolithography and etching technology, hot pressing, molding, injection molding, LIGA technology, laser ablation, soft lithography, etc.

(3) Fluid control of the microfluidic chip

Microfluidics is divided into passive microfluidics and active microfluidics. Passive microfluidic control, without the help of external force, completes various reactions through the capillary action of the liquid itself. Active microfluidic control precisely controls the reaction chamber in the chip combined with the valve device inside the instrument to precisely control the flow form of the liquid, quantitatively control the volume of the reaction sample, and allow the sample to participate in the reaction quantitatively to achieve precise control.

Passive microfluidics mainly includes the multiphase flow method, concentration gradient method, centrifugal method, and thermal capillary method.

Active microfluidics mainly includes dielectrophoresis, pneumatic method, electrowetting method, and magnetic method.

4. Microfluidic market capacity and prospects

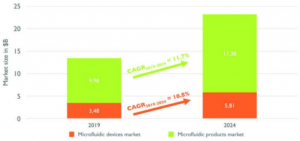

According to the latest statistics from Yole analysts, the global microfluidic product market reached US$8.7 billion in 2018, at a compound annual growth rate of 11.7% from 2019 to 2024, and is expected to reach US$17.4 billion in 2024. The two main applications are (1) point-of-care testing (POCT), (2) pharmaceutical/life science research (including sequencing, genomics, and proteomics). In addition, other microfluidic applications are also evolving.

5. Summary

5. Summary

Microfluidic chips will definitely be highly industrialized in the future. This is due to the irreversibility of the current market demand, the acceleration of the process, and the irreplaceability of the technology in certain major areas. The new economy represented by biomedicine is likely to use microfluidic chips to realize the transformation and upgrading of the current industry, and then have a profound impact on the entire economy.